Tutorial~ IKEA Hack: The INGO Sewing Table for my Singer 201-2

2:49:00 PM

I think I promised to write this tutorial up like, oh, 2 years ago?

|

| My 1937 Singer 201-2 in a IKEA dining table |

And since I hacked this INGO table, I've hacked another INGO table in a different way for a second machine (a Janome 6500*):

So now I owe you yet another post. But here we go.

I have a gorgeous Singer 201-2 from 1937 that my friend Erika over at Miss Sews it All found, restored, and passed along to me. It is the best machine ever. If you ever have the opportunity to own one for a decent price - get it. Now. They are amazing machines.

|

| Singer 201 in an IKEA INGO table |

When I got the 201 I didn't have a table or box to put it in. So I had to improvise. I had seen From Marta with Love's tutorial online for sinking a modern sewing machine in a INGO table, but why couldn't I do it for the 201, too?

|

| a Singer 201 basking in the glow! Sunk in an IKEA dining table, complete with original machine hinges! |

Here's the IKEA INGO table:

My issue was that these tutorials online have the modern machine sitting on a deck which is sunk below the table; with a 201, it needs to sit on the table slightly - these machines were originally on hinges anchored to the sewing table's or boxes' top:

|

| example of Singer hinges mounted flush with the box top - the same would be in a table mounted machine image courtesy of oldsingersewingmachineblog.com |

|

| example of a set of Singer table/box hinges image from singeroriginalvintageproducts.com |

Now my IKEA hack began!

- Singer 201 (or other vintage hinge-mounted sewing machine) and hinges

- Jig Saw

- Pencil/Marking tool

- Drill

- Sander

- wood pilot hole bits (like the largest one in this set* and ones slightly smaller than the diameter of the screws you'll use)

- Chisel (I have this set*)

- Utility knife

- Hammer

- 1 1/8" Wood-boring or spade bit (like this one*)

- Screws (about 10 x 1" wood screws; 2 x 1/2" flat head multi-material full thread screws; 4 x 2" #8 flat head multi-material full thread screws)

- Wood filler (make sure to buy stainable, like this*, if you're sealing the top and not painting)

- Polyurethane (I used this one*) and/or paint (I used a sample size of Behr's Marquee in SW6855, Sherwin-Williams "Dragonfruit" - sample sized is just the right size)

- cardboard piece, covered with felt (optional - to slide under your machine on the deck, to catch any oil drips)

WOOD CUTTING LIST:

(Cutting numbers based on a 2014 INGO table model, and, on my specifications for where I wanted my machine placed on the table top)

- (1) 18" piece and (1) 25 3/4" piece of 2x2

- 19"x 27 3/8" plywood sheeting (I used this one from Home Depot)

So - many of the photos I have are long gone from the production of this project. But I can still walk you through all of the steps, especially since most of what I did was a mish-mash of several different tutorials, modified for my use.

Here are several tutorials for your reference which were my reference when I was doing this-

From Marta with Love || Blue Dinosaurs || Make it Handmade || The Project Lady

1) Assemble the INGO table (frame, legs), but don't attach the table top yet.

2) Set the table top in place, do not screw. Set your machine on top and approximate where you'd like your machine to sit. Mark the frame of the table accordingly so that you know where to put your 2x2 bracings. Remove machine and table top.

3) Attach your plywood ledge's frame:

I pre-drilled holes in the frame of the table and attached the 2x2s to the inside of the frame with long 2" screws. Each 2x2 received 1 screw through the outside of the INGO frame to the 2x2. I suggest doing this part with the table flipped upside down, with the legs in the air; place 2x2s flush with the top edge of the table frame.

Sew at Home Mummy Tip:

Save the cardboard box and keep your frame and table set on this while you work

4) Attach the plywood.

Screw the plywood directly to the bottom side of the 2x2 frame you made and the INGO frame with 1" wood screws, first drilling pilot holes.

5) Attach the table top.

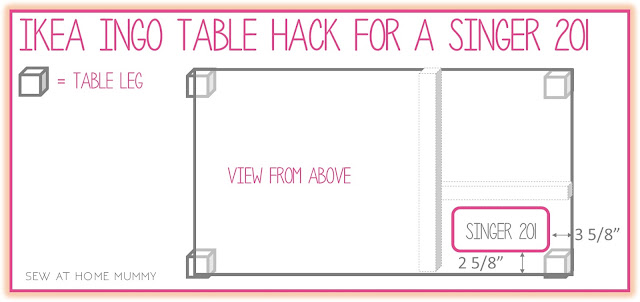

6) Place your machine back on the table top, and trace around the perimeter of the machine. Because the 201 actually sits slightly on the table top and not flush level with it, your hole to accommodate the machine will need to be slightly smaller than the perimeter that you just traced. Draw a line ¼" smaller than the line you just drew - so on the inside of the perimeter tracing, draw a line ¼" away. Make sure to accommodate for the plywood frame underneath - based on my 2x2 framing, my machine sits with it's edge 3 ⅝" from the right edge of the table, and 2 ⅝" from the front edge of the table, like so:

7) in the four corners of your inner line, and using a large drill bit, drill a pilot hole for your jig saw starting point. Using your jigsaw, carefully cut along the inner line to cut out the hole for your sewing machine.

8) Place your sewing machine in the hole, and make adjustments to your cutting accordingly so that the machine sits level in the hole. Sand edges to smooth.

9) Mark the table for the hinges; on the rear of the sewing machine you'll see 2 holes which accommodate the hinges - with your machine in place, mark on the table where these hinges would sit. Trace the hinges onto the table according to these marks. (Refer to The Project Lady's tutorial here for reference pictures - it's a great tutorial)

10) Using your wood boring bit, carefully drill out a notch large enough to accommodate the head of the hinge - be careful not to drill all the way through, but only as far as to make the hinge flush with the table. Use your chisel to finesse the notch so that the hinges sit nicely. Next, notch out for the hinge stem using a utility knife (first score the lines so that the chiseling doesn't chip or splinter the notch) and a small sharp chisel.

11) Ensure the hinges and machine all fit nicely. Remove machine, using wood filler to patch or repair any splinters and screw holes, and finish table (stain, paint, or both!).

Sew at Home Mummy Tip:

Sew at Home Mummy Tip:make sure to use a stainable filler - I used a dries-white filler not knowing that you'd be able to see the fill areas once I sealed the top (this isn't as important if you're painting the top a solid color).

12) Screw your hinges into the machine, then drop the machine in place. Screw hinges in place using ½" flat head machine screws.

13) (optional) I covered a piece of cardboard with grey felt and slid it on the plywood decking under my machine to catch any excess oil drips I may miss wiping off when I'm oiling the machine.

So there you have it! A tutorial 2 years in the making, finally done! And since writing this tutorial up, I've added these casters* to the legs of the 201-2 and Janome 6500*'s INGO tables to make them easier to move around (one of the smarter things I've ever done).

Hopefully this tutorial inspires others to make their own IKEA-hacked sewing table for their vintage machines (and if you do end up doing this for your machine, email me some pictures {here}, I'd love to see them!)

Also, make sure to check out my sewing room related boards on Pinterest - I have a ton of ideas pinned there!

3 comments

Fantastic tutorial Erin, why do you like the caster's doesn't it make the table feel unstable while sewing?

ReplyDeleteComment via email from "Priscilla Reed": Most women wouldn't even dare such a project. That's really impressive. Being a woman who has always worked with powertools (my dad taught me), I understand the expertise needed. Bravo!

ReplyDeleteThanks Priscilla! My dad taught me as well; he had 3 girls, no boys - and we were always his second set of hands on the farm! Learned to use power tools at an early age, learned to drive on a big blue Ford tractor...it was an awesome childhood!

DeleteI ♥ to hear from you!

Thank you for taking the time to leave a comment or for asking me a question. Rather email me? Reach out at sewathomemummy@gmail.com.

I like to email everyone back when they've commented - so if you're a no-reply blogger, make sure to leave your email address in your comment so I can share the love back atcha!